Bhosari, Pune, Maharashtra

- GST NO. : 27BNIPB2434D1ZI

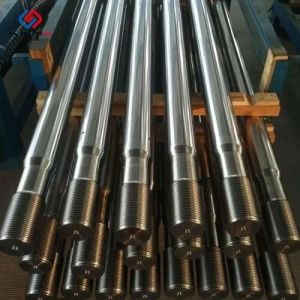

Forged Step Shaft

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Shape | Round |

| Application | Automotive Use |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Color

Silver

Feature

Durable, Fine Finishing

Finishing

Coated

Looking for "Forged Step Shaft" ?

Piece

Explore More Products

Our Blogs